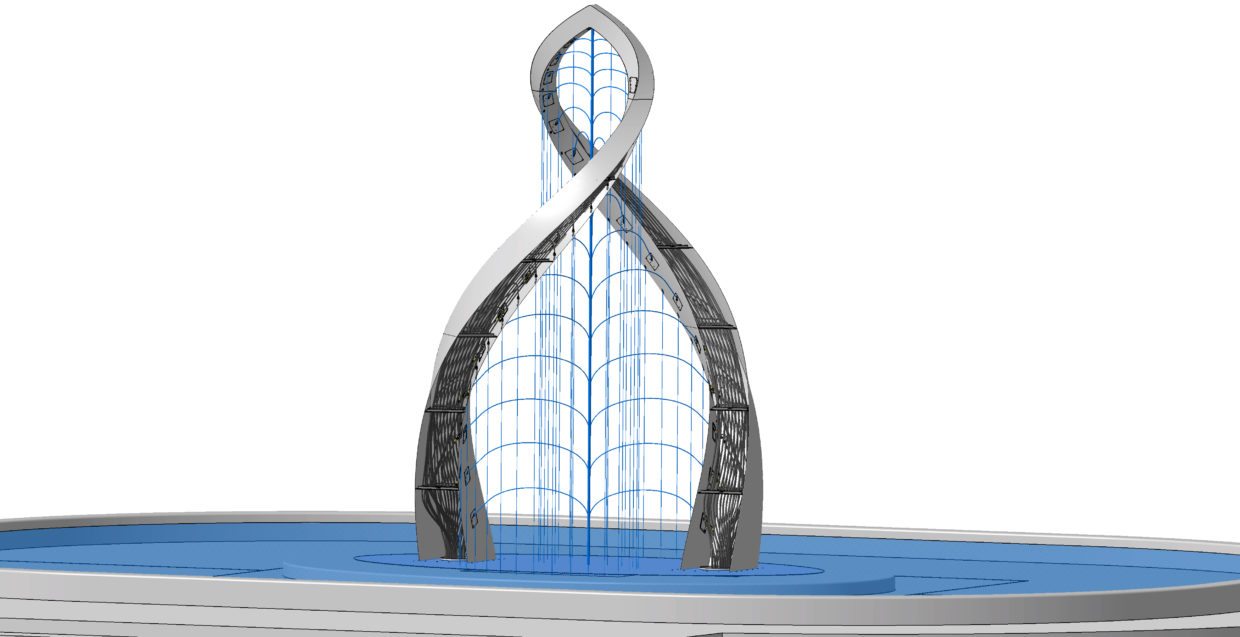

What gives us the edge? Our ability to automatically generate designs that follow an underlying geometric DNA. We call it DNA Modelling.

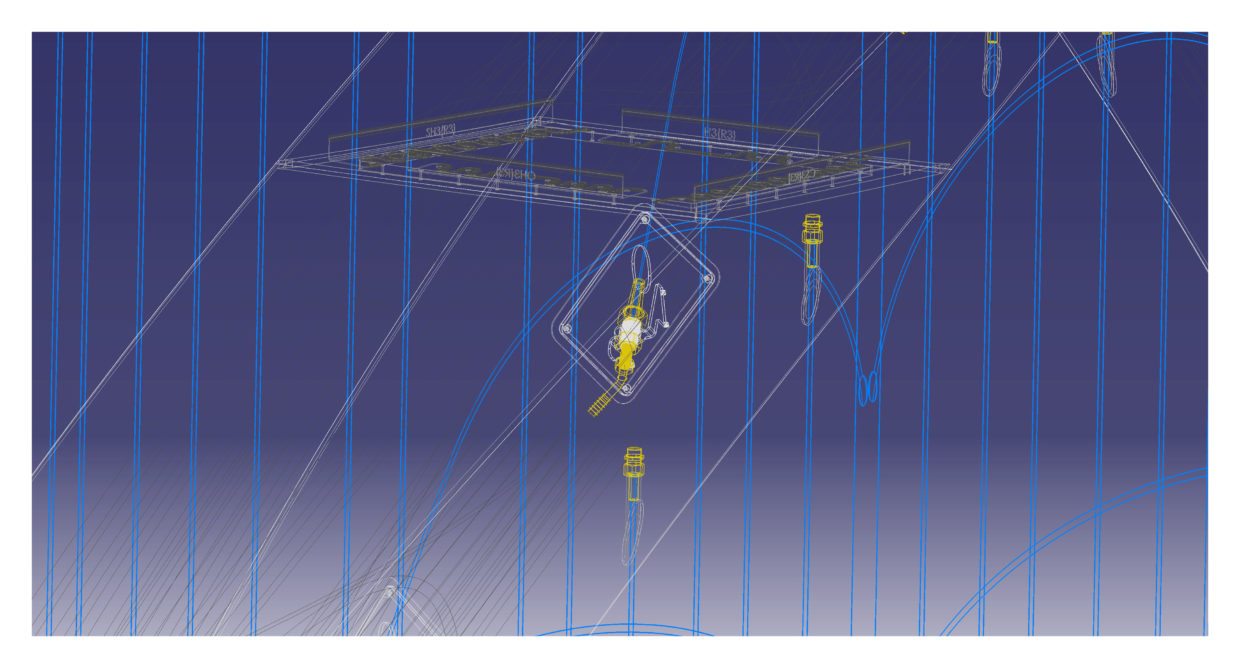

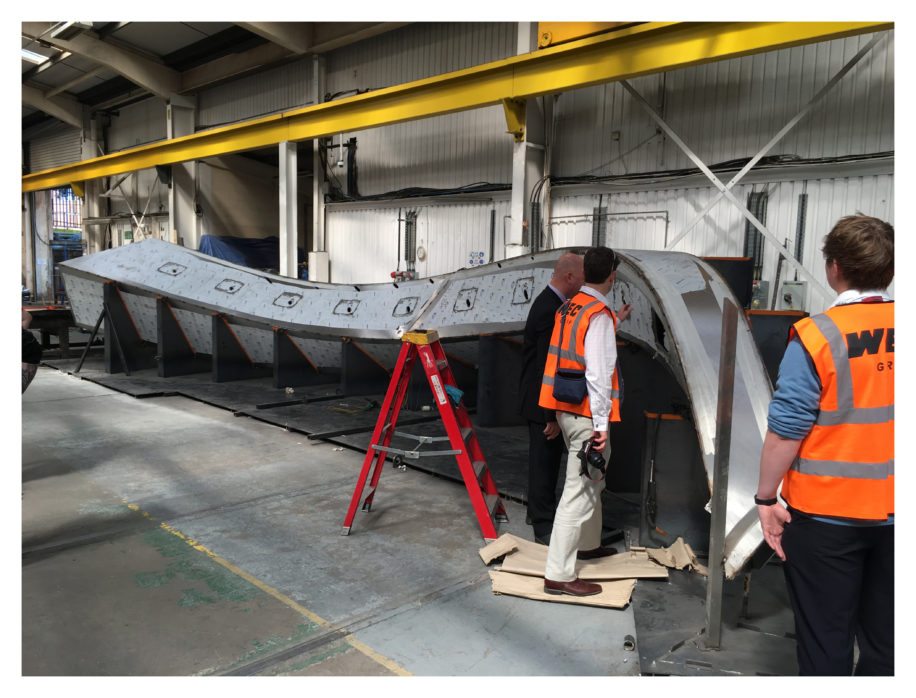

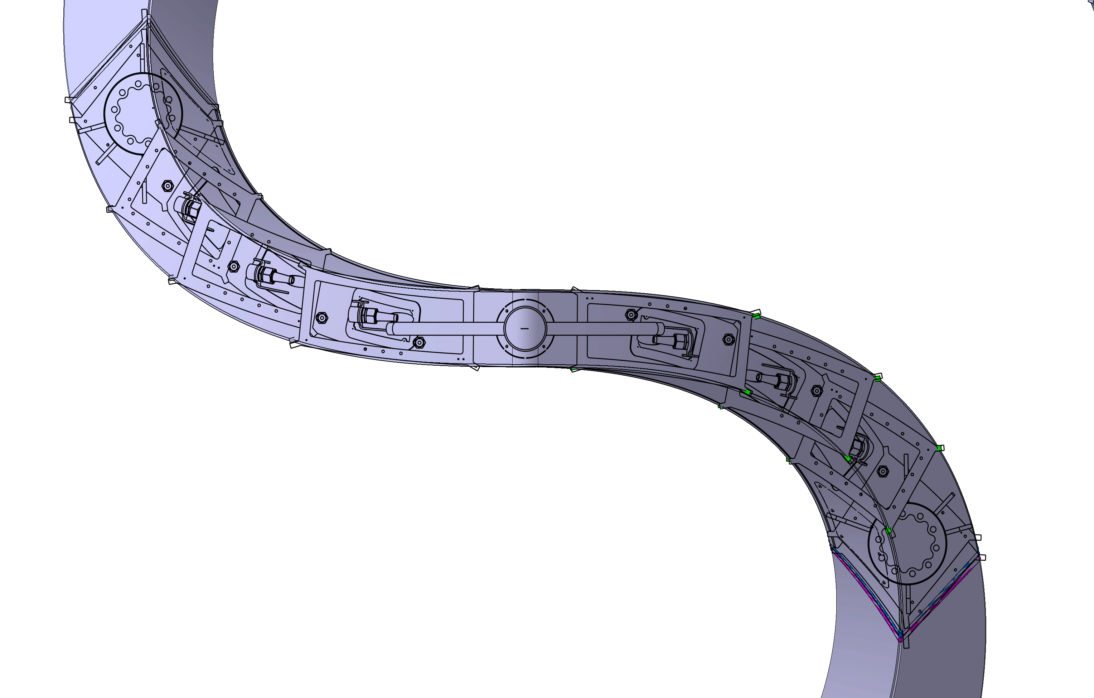

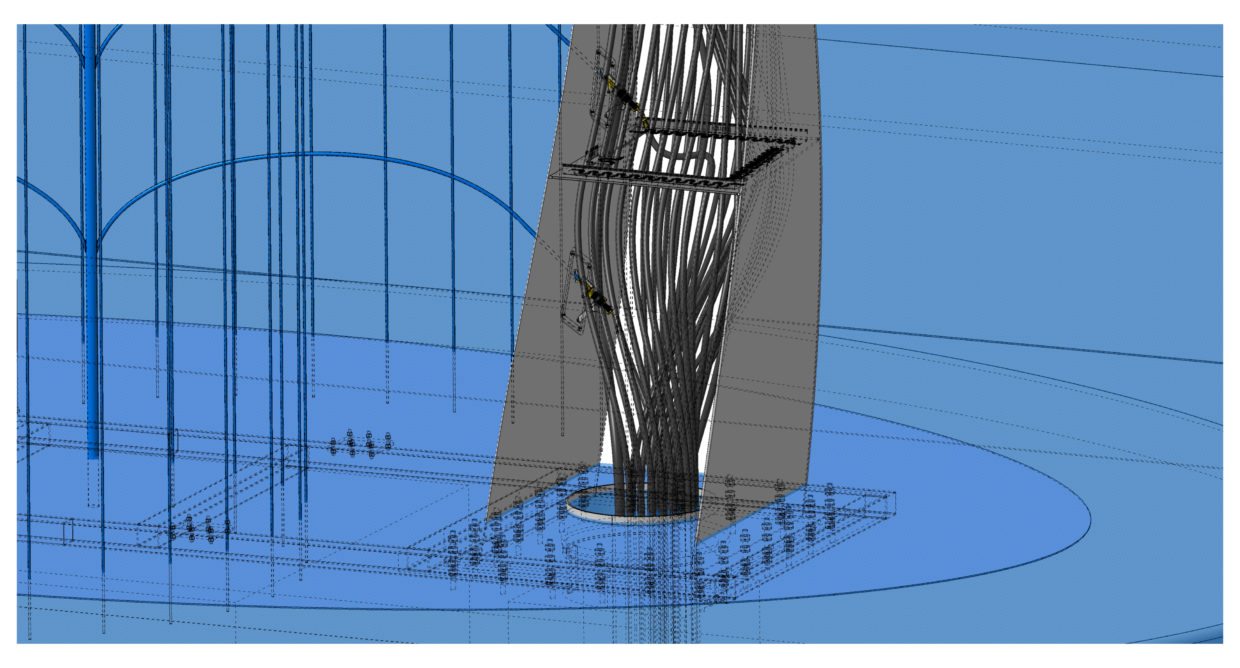

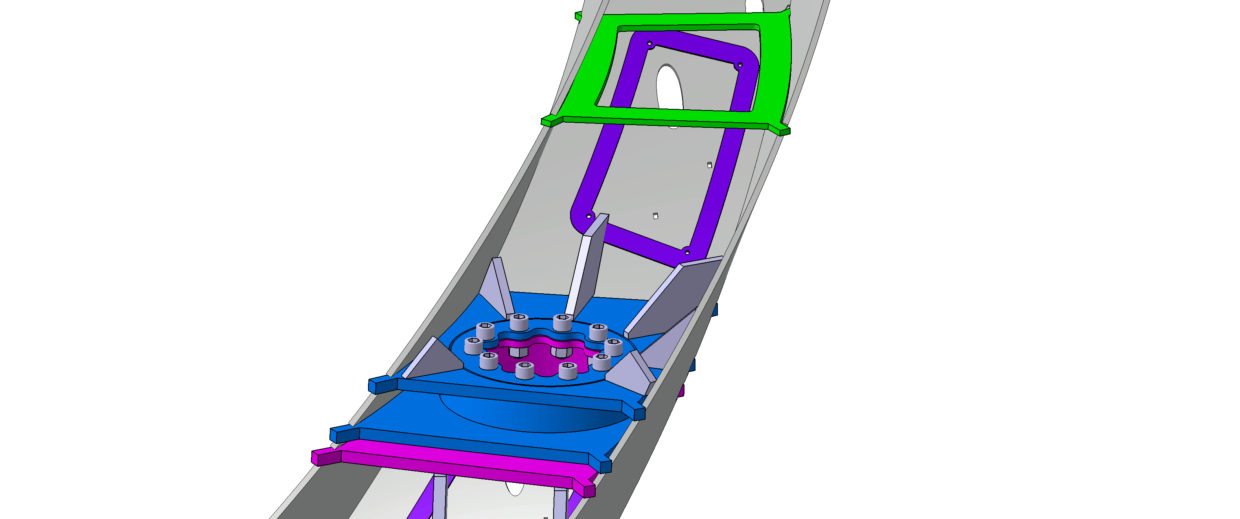

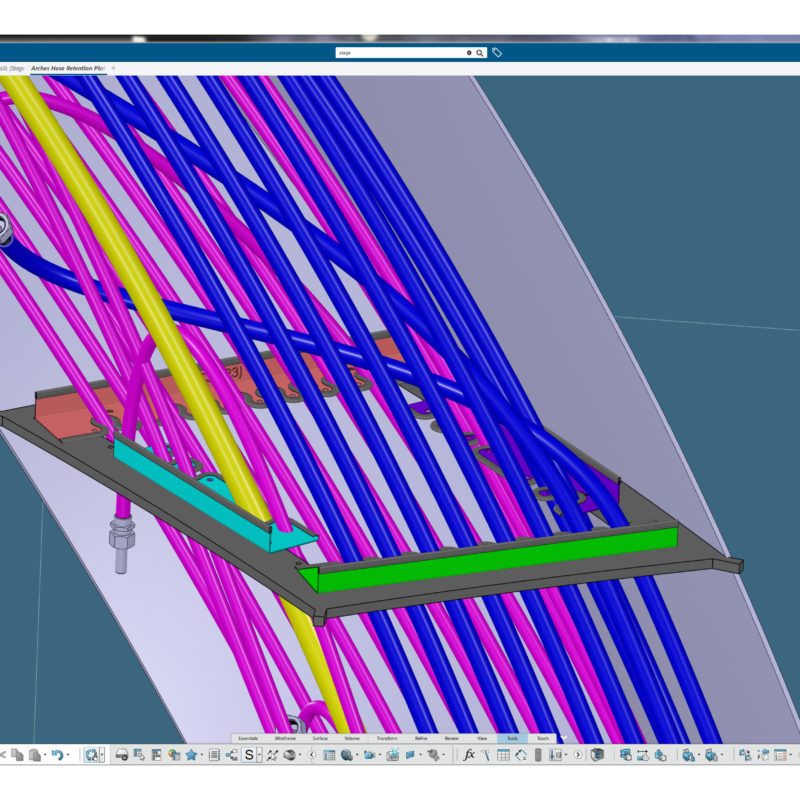

Now it was onto designing the internal details. We needed to work out how to support the structure and attach the various components for its water displays. The task was complex. There was lots of heavy hardware to support, and we needed to allow access for fitting and repairs.

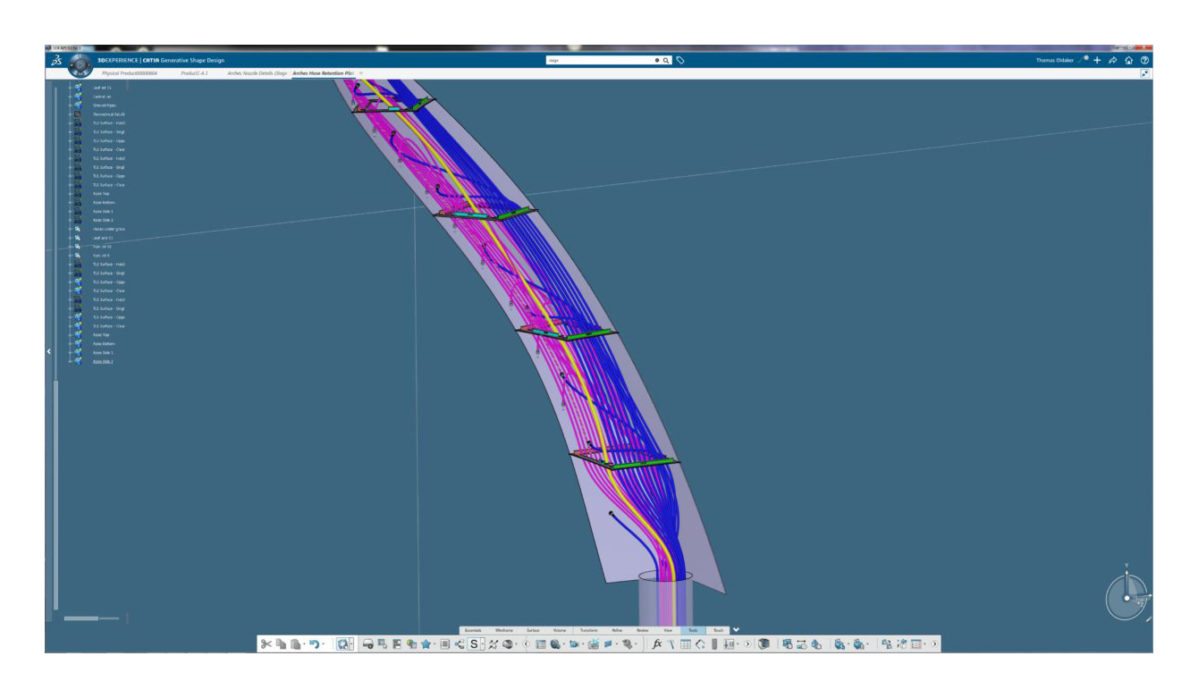

Our DNA Modelling methodologies played a big part in this and every stage of the project (just like all our projects). How does it work? We calculate a design’s fundamental geometry. From this, we create automated parameters. These parameters allow us to generate limitless variations of any part or component, which all stay true to the design’s geometry.

For example, we created a parameter to grow nozzle hatches up the sculpture’s surface, including all the cutting profiles and internal details. Another parameter allowed standard nozzle brackets to cut themselves to fit across the curved surface. And each nozzle was tagged, ensuring they were positioned correctly every time.

Our DNA Modelling delivers another big advantage. If designs or parts change as a project progresses, the parameters update everything automatically and instantly. So clients get rapid and flawless results, saving them time and money.

That’s exactly what happened with the Arches of Oman. The design adjusted straight away to our tweaks and adjustments, such as changing connector diameters and swapping joints. Even aesthetic choices, like switching from button-head to countersink screws, updated immediately in our designs. The main design areas in the internal structure were:

- nozzle brackets

- hatches

- supporting ribs

- apex to tusk join

- central jet

- leaf and rain nozzles

- hose retention plates

- hose routing.