Challenge

Tackling complex, multiple component assembly challenges.

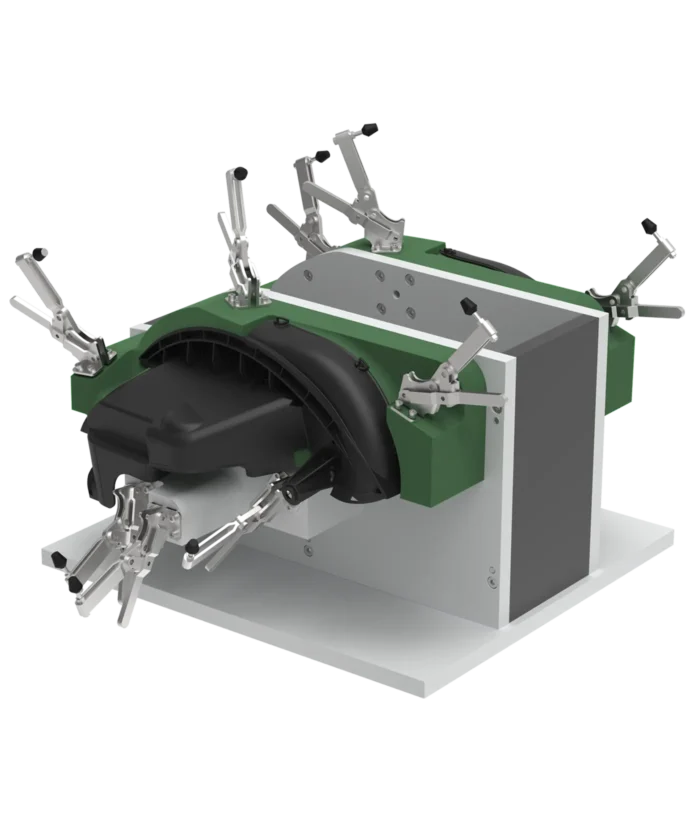

Experts in manufacturing high-precision parts, a client required bespoke fixtures to support the assembly process and ensure accuracy and consistency throughout production for a multitude of parts including air intake systems for automotive applications.

Solution

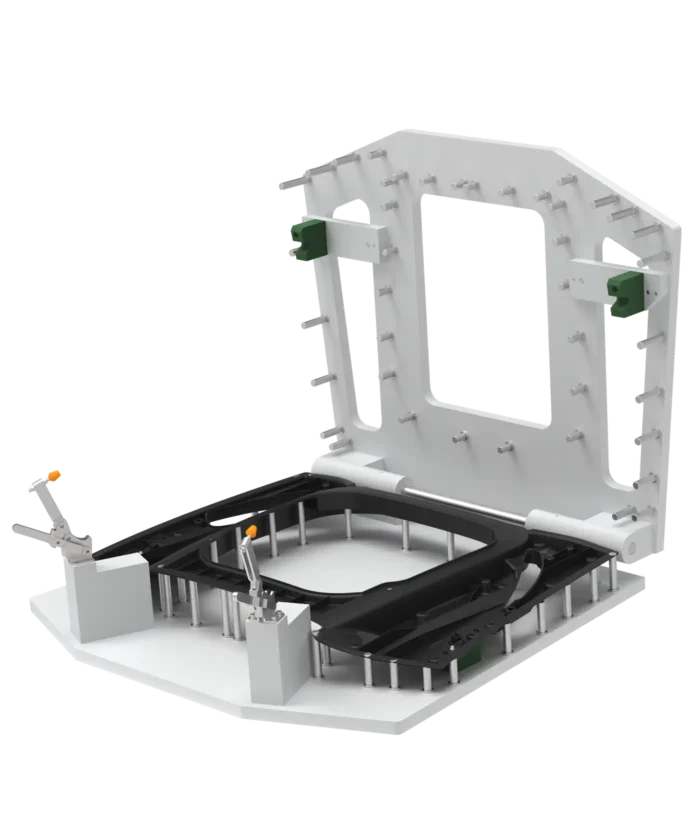

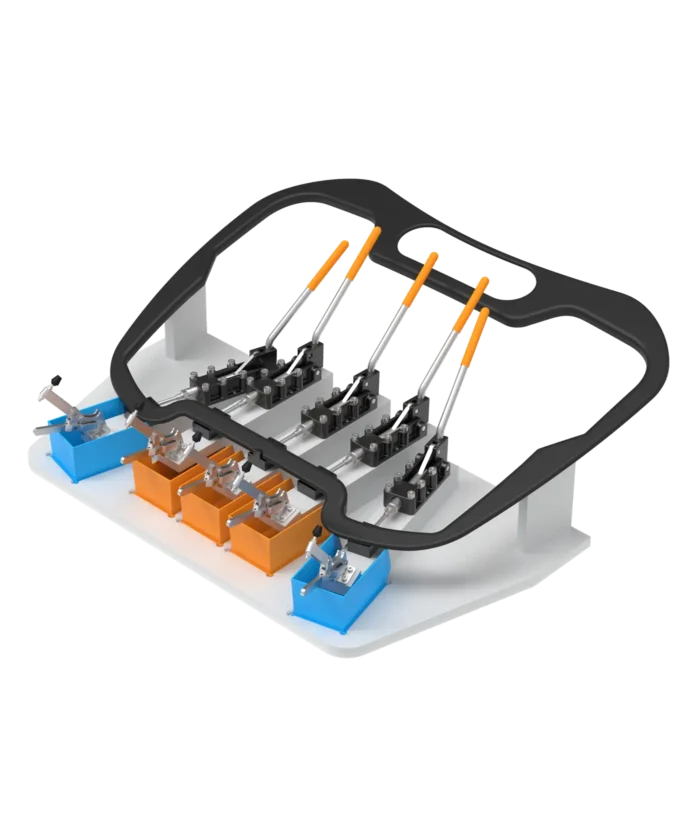

Custom specialised fixtures tailored to the unique needs of the parts were designed, holding the parts securely during assembly and ensuring accuracy throughout production. Generative Parametric’s experience spans several types of fixtures:

- Checking Fixtures: holding parts for metrology, ensuring parts meet precise size and positioning requirements.

- Paint Fixtures: holding parts steady during painting, preventing defects and ensuring a smooth finish.

- Cooling Fixtures: preventing warping by maintaining shape during the cooling process, reducing distortion and maintaining integrity.

- Compensation Fixtures: for parts that warp during production, designing fixtures that counteract bending and distortion by applying reverse force, ensuring correct geometry through advanced CAD and material compensation.

Key factors addressed

- Customization: each fixture was tailored to the specific challenges of the parts and assembly, ensuring efficient, effective solutions for complex automotive components.

- Quality and Reliability: fixtures ensured precision, meeting automotive standards for consistency and accuracy.

- Innovation: in compensation fixtures, using generative design and advanced CAD, solutions were created for complex geometries and material behaviour, ensuring high-quality results even in highly specialised applications.

- Cost-Effectiveness: while custom solutions like cooling fixtures can be expensive, Generative Parametrics work closely with clients to design solutions that balance cost with performance, ensuring that the investment in complex fixtures delivers tangible benefits.

Outcome

Improved assembly efficiency and reduced defects.

Customised fixtures provided the precision needed for high-quality production while minimizing downtime and operational costs.

The ability to manufacture complex parts with a higher degree of accuracy and consistency has helped the client maintain production schedules and reduce operational costs.

A deep understanding of materials, design challenges, and manufacturing processes has earned Generative Parametrics a reputation for delivering high-quality fixtures that support the most intricate and demanding assembly tasks. As industries continue to evolve, the forefront of designing innovative solutions to meet the needs of clients across various sectors, including automotive, is maintained.