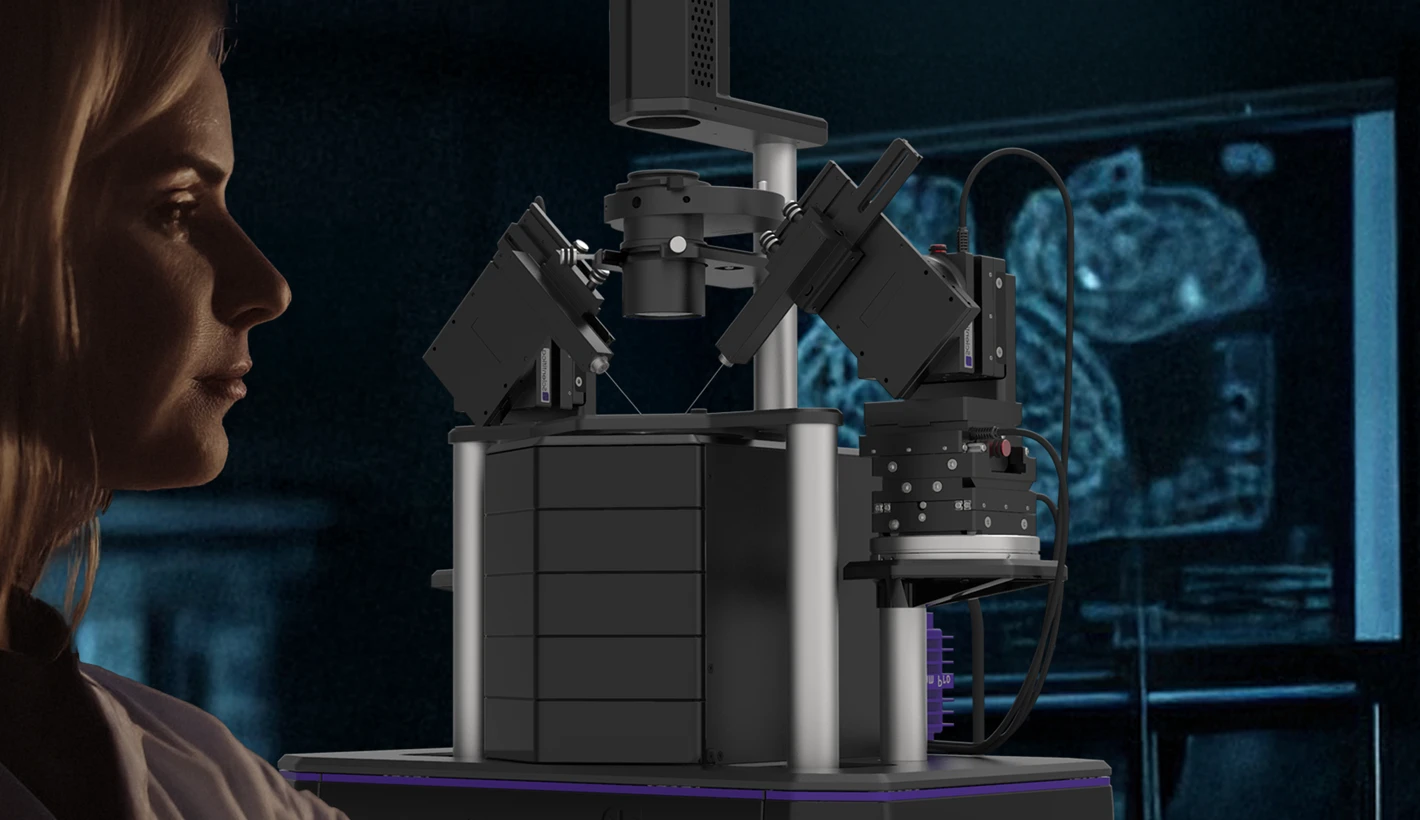

Inverted Microscope

Driving breakthroughs in electrophysiology research

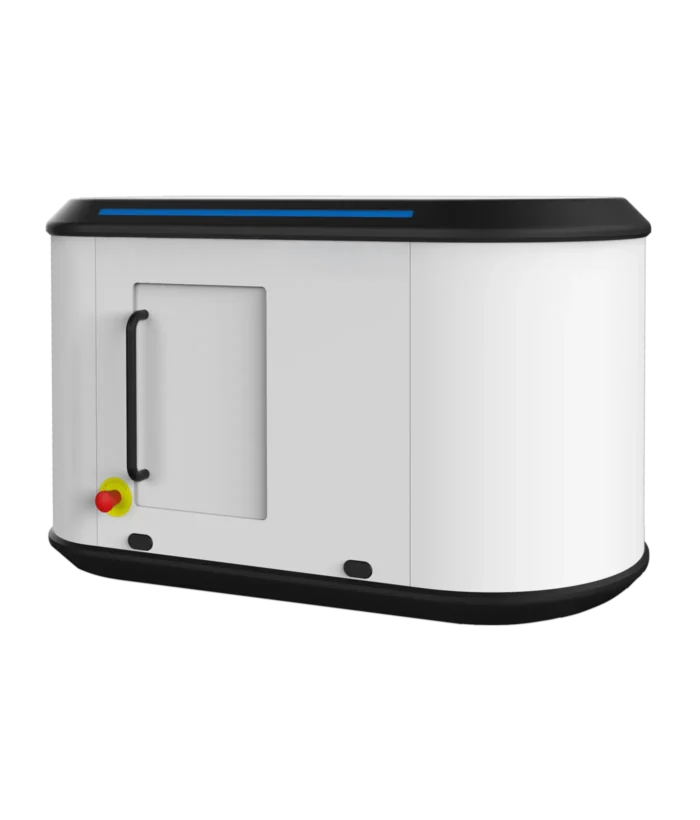

The enclosures had to meet multiple demands:

In addition, the system had to pass rigorous factory acceptance testing (FAT) to guarantee safety and reliability in diverse laboratory settings.

Resilient Construction

The enclosures were crafted from corrosion-resistant materials to withstand exposure to humidity, chemicals, and temperature fluctuations, ensuring long-term durability and reliability.

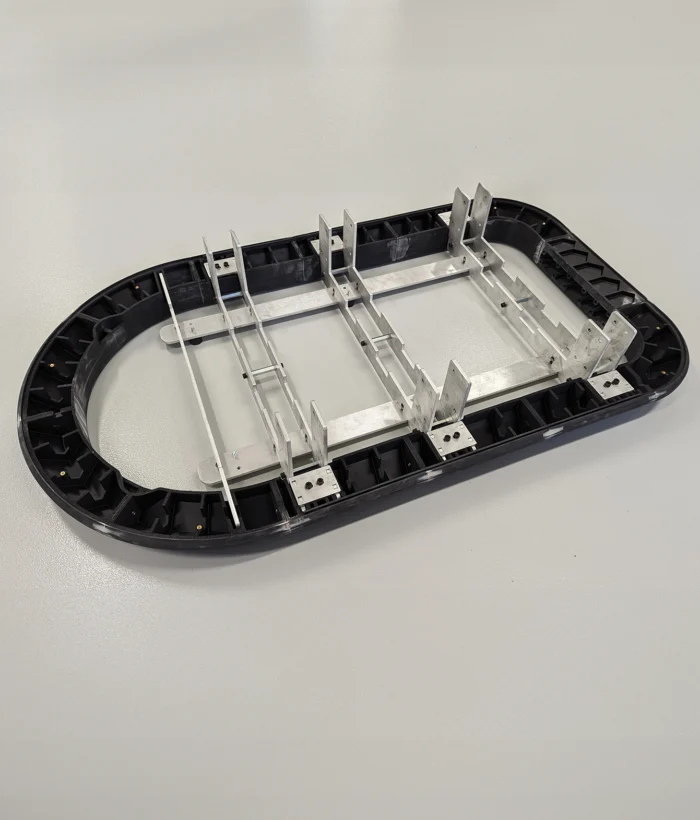

User-Friendly Maintenance

Generative Parametrics incorporated poka-yoke mechanisms, preventing assembly errors and allowing for swift, hassle-free servicing. Modular components enabled technicians to quickly access and repair parts, minimizing downtime and operational disruptions.

Safety First

Electrical components were designed to meet or exceed regulatory safety standards, passing FAT requirements and ensuring the system’s operational security.

The bespoke enclosure system delivered exceptional performance, offering uninterrupted operation even during extended daily use. Its sleek, modern design reinforced the client’s reputation for technological sophistication while aligning with the brand’s aesthetic identity.

The project demonstrated how innovative design and engineering can meet diverse laboratory needs, providing a solution that merges durability, usability, and visual appeal.